No-Hub Fitting Restraints: What You Need to Know to Protect Your Property

Piping systems are essential for transporting fluids from one location to another in a safe and sanitary way. However, it is still far too common today for contractors of above ground cast iron hub-less piping systems to underestimate the importance of utilizing no-hub fitting restraints, which serve to prevent no-hub pipes and fitting from separating under thrust force.

Consequences of Forgoing No-Hub Fitting Restraints

The decision to go without no-hub fitting restraints can prove to be a disastrous and extremely costly, as was the case in high profile cases like the Lucas Oil Stadium disaster of 2008 and the UPHS Translation Research Center flood of 2012.

The Lucas Oil Stadium Disaster of 2008

While the Indianapolis Colts’ new stadium was widely regarded as a marvel in design and amenities when it was unveiled for public use in 2008, it had first become a prime example as to why the failure to install no-hub fitting restraints can prove disastrous.

To make the story short, the plumbing contractor had to work quickly due to delays. Shortly following the installation of millions of dollars worth of IT equipment in the stadium’s basement, a significant rainstorm swept into the area. In the absence of fitting restraints, three of the rainwater leader system’s no-hub cast iron rain leader joints failed, leading to a flood in the basement, substantial monetary damages and a series of lawsuits and project delays.

Evidence of the rushed construction job continued even until 2014, as corroded pipes and deteriorated pipe insulation added insult to injury, resulting in total costs of around $15 million as a result of the three different incidents of pipe failure.

The UPHS Translation Research Center Flood of 2012

The story is similar in the case of the University of Pennsylvania Health System (UPHS) Translation Research Center Flood of 2012.

Shortly after the project was completed and the owner began moving into the building, a massive rainstorm hit the area, causing significant pressure to build in the building’s piping systems. Flooding inside the building ensued following the failure of an unrestrained 12-inch rainwater leader, which went on to crash through the ceiling of the fifth-floor stairwell.

Top Risks of Excluding Fitting Restraints in Construction

The two most common reasons for pipe and fitting join failure are hydraulic jumps and lack of an overflow point.

Hydraulic Jump

A hydraulic jump occurs when water traveling down a vertical pipe at terminal velocity runs into slower-moving water moving through a horizontal and begins to back up through the vertical pipe as a result.

Depending on the severity and duration of the rain flow, the water backup caused by hydraulic jump could result in the separation of the pipe from its fitting. This is precisely what happened in the 2012 flood of the UPHS Translational Research Center, which experienced around five inches of rain per hour and 82 pounds of thrust.

No Overflow Point

The lack of an overflow point can also pose a serious threat to the integrity of a building’s piping system. As an example, imagine a multi-story high rise building with commercial units at street level and residential units above. If the stack serving the upper residential floors lacks an overflow point, blockage at the street level can cause multiple stories of head pressure to build up quickly and lead directly to pipe failure.

Most Common Reasons Why Restraints Are Not Installed

There are two primary reasons why many construction projects, even those completed within the past five to ten years, lack no-hub fitting restraints.

1. Proper Installation of Restraints Costs Times and Money

Bringing a construction project through to completion is a labor-intensive and costly endeavor. Constructing an entire drain, waste, and vent system according to the standards prescribed by the combination of the International Plumbing Code, the Cast Iron Soil Pipe Institute (CISPI) and the pipe and fitting manufacturer’s installation instructions is hard enough, leading contractors to omit or generally overlook the need for restrains unless specially requested.

2. Many Installers are Unaware of the Code

While the International Plumbing Code does spell out the need to install no-hub fitting restraints in Chapter 3, the Code did not specifically address the issue before 2009. Even then, all of the other codes on drain, waste and vent systems are contained in Chapter 7, leading many to overlook the earlier mention of no-hub fitting restraints.

Problems with Field-Devised Restraint Methods

Field-devised restraint methods represent a creative, do-it-yourself approach to constructing pipe restraints. While not installing any restraints is dangerous, using field-devised restraint methods also comes along with its share of concerns, notably the fact that they are often:

Untested, often relying on techniques and materials outside standardized use. As a result of the lack of uniformity and the possible misuse of tools such as riser clamps in thrust restraint, the reliability of field-devised restraint devices cannot be accurately measured until it is too late.

Labor-Intensive, taking a considerable amount of time and money to measure, cut and fabricate.

Temporary, only using the field-devised restraint to perform tests. For example, it was once common practice for plumbers to shackle the pipe and fitting together before the inspection to allow the pipe system to carry water up to a 10-foot head level satisfactorily. Once the inspection was over, the shackling could be removed, leaving no restraint in its place.

HoldRite’s Engineered No-Hub Fitting Restraints

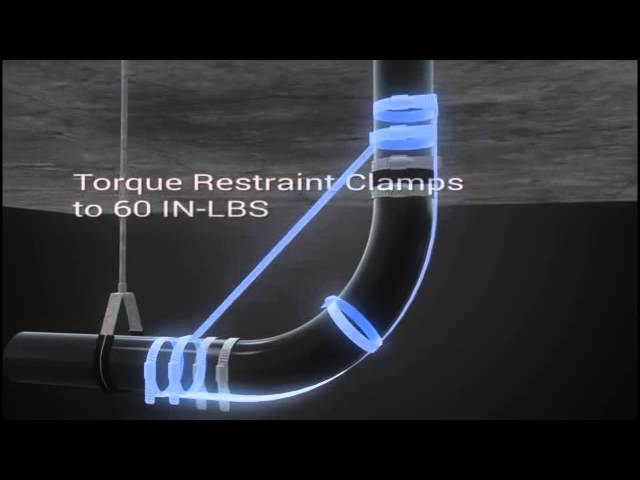

The HoldRite #117 Series No-Hub Fitting Restraints are the ideal solution for restraining hub-less cast iron soil pipes against separation during high thrust conditions.

HoldRite No-Hub Fitting Restraints are:

Reliable

Built with top materials such as stainless steel, black iron, or galvanized components and engineered to meet plumbing codes, pipe manufacturers’ installation instructions, and the CISPI installation handbook.

If properly installed according to manufacturer instructions, the restraint systems are rated for up to 50 feet of head pressure, blowing away the 10 feet of head pressure required by the International Plumbing Code.

Less Expensive

Thanks to reduced costs in terms of time and materials, contractors save from 30 to 50 percent in “total installed costs” by opting for HoldRite’s engineered solutions.

Easy to Install

Installs in minutes without any on-site cutting, bending, measuring, or modifications necessary. Also, no special tools are required for installation, as all components are included in each kit.

Learn More About HoldRite N0-Hub Fitting Restraints

A proven partner in the plumbing industry for over thirty years, HoldRite products are made in the USA and are available through plumbing wholesalers across the country. Should you have any questions or wish to learn more about the benefits of using our No-Hub Fitting Restraints, please get in touch today or give us a call at 800-321-0316.

Contractors, wholesalers, and engineers can also consider taking advantage of the HoldRite No Charge VIP Estimating Service, where you can electronically transfer your construction plans at no cost and receive a comprehensive cost-saving analysis performed by Estimators with over twenty years of plumbing experience.

We look forward to working together to find the right plumbing support solutions for you to complete your project effectively and under budget.

Enable Performance and Targeting Cookies to view this content. Update your cookie settings to view this content.